|

DIY High Flow 8V Head

I certainly am not an authority but I have

spent a lot of time researching and testing

8V 951 heads in a quest to develop a low

cost solution for larger motors.

Obviously the 16V is the best solution but

the cost is significant and in many cases

not practical. I wanted to do a head that

would perform well and keep in

line with the spirit of low cost Hybrid

Stroker motors. Outlined in this thread is

my current progress. Much thanks to all who

have helped me along the way, especially Sid

and MM.

The results and the total cost of the effort

are also outlined below:

951

Head.........................................$0

(head from my 2.5L)

47mm +2

Valves..............................$108

(set of 4,

see here)

Valve

Guides....................................$34

Valve

Seals......................................$36

Valve

Springs...................................$84

(set of 8,

see here)

Install

Guides...................................$160

Remove Valve

Seats.........................$48

Install New

Seats.............................$100

Surface

Cut......................................$60

Competition Valve

Job......................$265

Total Cost................$895

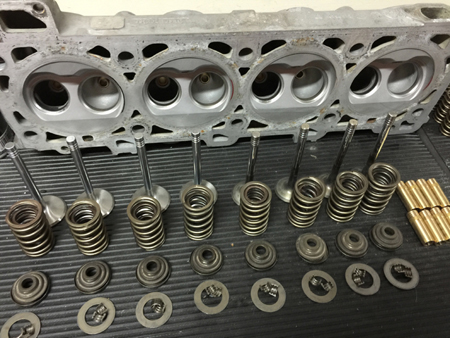

I started with the 8V 951 head from my 2.5L.

I disassembled the head, cleaned it, and

carefully inspected it. I inspected the

ceramic exhaust ports, inspected the deck

for pitting in the seal ring areas,

inspected how much the head had previously

been decked. Some may laugh but below is a

picture of my valve spring compressor. It

consists of an 8" C clamp from Harbour

Freight and a modified socket (total cost $9

)

|

|

|

|

|

|

|

|

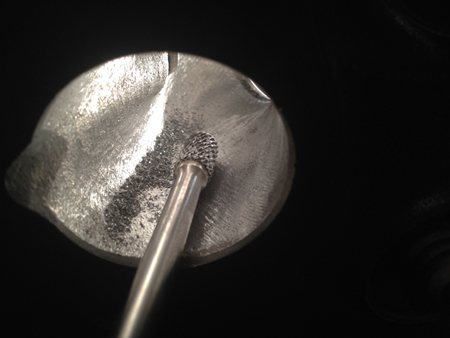

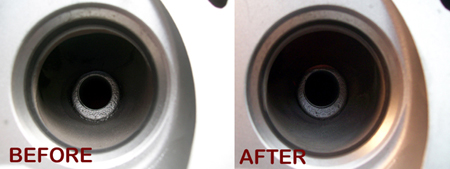

The next step was to do the initial porting.

I did much of the porting before the new

guides or intake seats were installed. In

this way I did not have to worry about

damaging the guides or the seats while

removing much of the port material. The

approach I took to porting was two fold.

One, to clean things up especially in the

throat area. I found on the flow bench that

cleaning up the bowl area right above the

throat resulted in improved flow. Secondly,

to increase the size of the intake port to

accommodate the bigger intake valve. My

approach was to maintain the port shape

while making it bigger. The intake valves I

used were 47mm which are 2mm bigger than the

stock intake valves. Therefore my approach

was to remove 1mm from all the walls of the

intake port as shown below. |

|

|

|

|

|

|

|

|

|

Below is a picture of all the tools I used

for doing the porting. All of the tools were

purchased at Harbour Freight with the

exception of the inside calipers and the

carbide bur (McMaster 4324A32). My porting

technique was slow and careful. I took A LOT

of initial measurements using the inside

calipers. I also used a technique in which I

used a drill bit to make several 1mm deep

holes as guides for how much material to

remove. I removed quite a bit of material

from around the guides. Be careful not to

remove too much material in the lead up to

the guide (see yellow circle above). I

probably spent over 20 hours porting the

intake ports. It is very important to make

the ports as similar as possible in order to

promote equal flow. My ports flowed within a

few cfm of each other on the flow bench. |

|

|

|

|

|

|

|

|

|

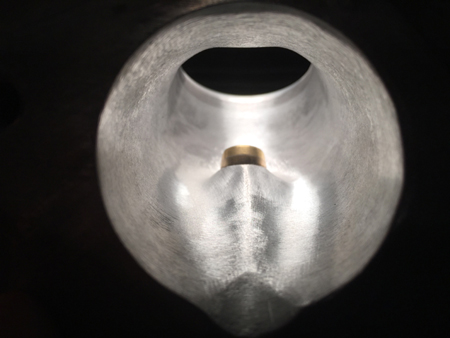

Once the initial porting was complete, the

head was taken to the machine shop to have

new guides and intake seats installed. I had

the machine shop bore out the seat throat to

within 0.005" of the final throat dimension.

I had them bore down into the bowl as shown

below as a guide for porting the bowl. At

this stage I completed the porting of the

intake ports. |

|

|

|

|

|

|

|

|

|

I also cleaned up the exhaust ports both

around the seats and at the header interface

using sanding rolls as shown below. The

ceramic often does not line up with the

casting and this can be smoothed out to a

large extent. |

|

|

|

|

Before |

|

|

After |

|

|

|

|

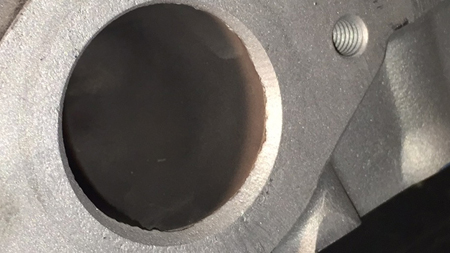

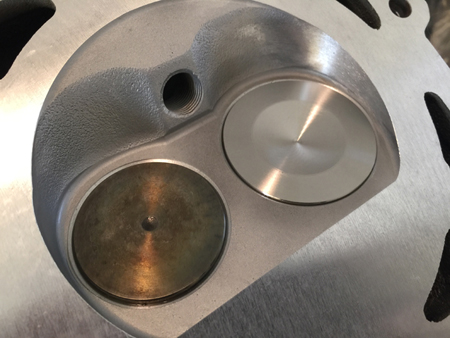

I also did some work to the chamber to

de-shroud the intake valves. My bore size is

102.3 mm and therefore I could remove some

chamber material. I used the head gasket to

determine how much material could safely be

removed. I marked the deck with a Sharpie as

a guide then used sanding rolls to remove

material as shown below. I was very careful

not to damage the seats. |

|

|

|

|

|

|

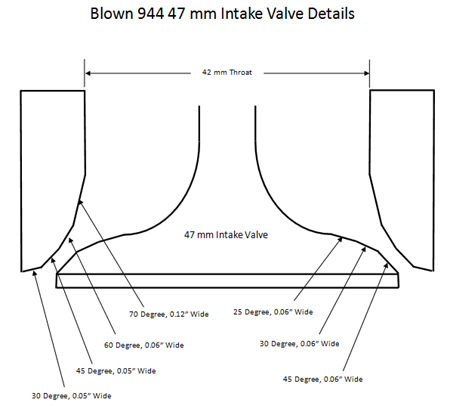

Once this work was completed, the head was

send back to the machine shop to have the

valve job done and to be assembled. The

valve job is SUPER important. Choose a shop

wisely. The intake dimensions I used were

developed by blown 944 (Sid) and I used them

with great results. |

|

|

|

|

|

|

The intake valves are one piece valves and

were purchased from SI Valves for $27/each.

SI has stock intake valves (45mm) and +1

(46mm), +2 (47mm), and +3 (47mm). I used

47mm valves due to my bore size (102.2mm).

On my flow bench I found very little

improvement in flow was obtained above 47mm

for my bore size. The exhaust valves are the

stock sodium filled valves. |

|

|

|

|

|

|

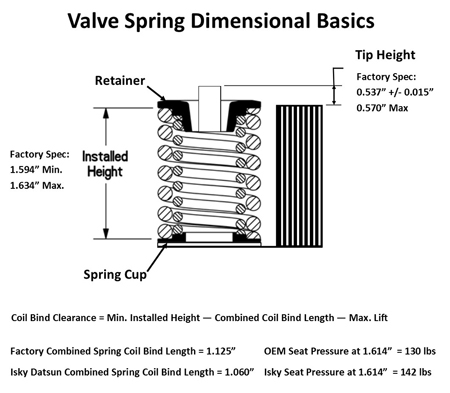

Shown below are some basics with respect to

valve springs. The first head I built, I was

pretty ignorant to these details. Do your

self a favor and get familiar with this

diagram. Do not assume the shop you use will

get the details right. Verify EVERYTHING. |

|

|

|

|

|

|

I was intending to run a high lift cam

(0.525" intake lift) and using the formula

above it became clear that the stock springs

were going to bind. In an effort to find a

low cost solution I was able to find some

springs for a Datsun 280Z that fit perfectly

in the stock retainer and spring cup and

provided a bit more seat pressure (138 lbs

vs 130 lbs) while having 0.065" more spring

travel. The springs are made by Isky Cams

(ISK7005-8). As an added bonus, the springs

are half the price of the stock springs. |

|

|

|

|

|

|

I was able to measure combined coil bind

length using a vise and calipers as shown

below. Coil bind clearance would be defined

as the amount of spring travel remaining

before coil bind at the minimum spring

height. A safe minimum coil bind clearance

would be 0.060". Some have run as low as

0.030" coil bind clearance in race

environments. Running these low of

clearances requires real precision in

determining the physical dimensions of each

valve. Also, keep in mind that as clearance

is reduced, spring life is also impacted. |

|

|

|

|

|

|

I had the head decked a few thousands just

to clean things up for the Cometic MLS

gasket. |

|

|

|

|

|

|

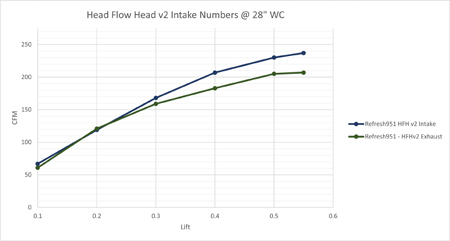

The completed head was flowed on a Superflow

flow bench at 28 inwc and the results are

shown below. The results show that cleaning

up the exhaust port and having a proper

competition valve job makes a huge

difference in an already outstanding exhaust

port. Also, the larger valve size in

conjunction with proper seat and throat

dimensions resulted in significant

improvement in intake flow. |

|

|

|

|

|

|

|