Block Preparation:

Sid's original Hybrid Stroker concept

was to use an inexpensive 2.5L block and

partially fill the water jackets around

the open deck with Moroso Block Filler.

I personally think this provides an

excellent platform for high power and

these blocks are available in abundance.

One could also use a 3L block which may

provide additional benefits such as

windage ports and raised water jacket

floor.

Preparation steps:

1) Block Cleaning -

I had my machine shop tank clean the

block (cost was $100)

2) Additional cylinder water jacket

surface cleaning -

I used CLR and a small wire brush to

prep the surface of the cylinder water

jackets to promote filler adhesion.

After brushing with CLR, I did a final

clean with soap and hot water.

3) Fill the cylinder water jacket

with block filler -

After final cleaning, I used wet paper

towels (highly technical) to block the

hole to the oil filter housing and stuff

the front water pump flow area (see pics).

I decided to prevent water from entering

the cavity within the oil filter housing

to prevent oil/water mix in the event of

a oil filter seal issue. The flow is

very limited in that cavity and I cannot

see it providing much cooling benefits

and I have had no oil temp issues. The

block filler I used was Moroso

#710-35571 which cost $20. A 1 gallon

container was plenty. I mixed it per

container instructions poured it into

the jacket area with a funnel. Make sure

the block is level and mark the block

filling height before filling. I then

used a rubber mallet and essentially

tapped on the block for about 30 minutes

to work air out of the filler. Once the

filler adequately set (about 12 hours) I

pulled the paper towels out and cleaned

up the surface of the filler around the

water pump passage at the front of the

block.

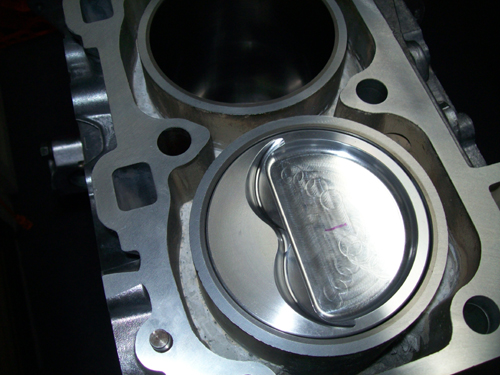

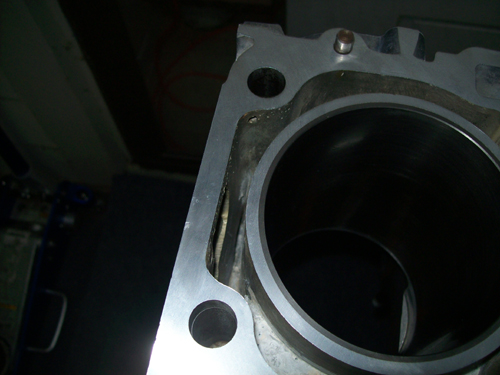

4) Install ductile iron sleeves -

I relied on my machinist for this. Make

sure your machinist knows what they are

doing! My guy ordered and installed the

ductile iron sleeves. Make sure the

chamfer at the top of the sleeve is

minimal (generally to aid in getting the

rings in) as if it is too big it may

cause head gasket sealing issues (mine

was good but close). Also, a bit of

aluminum block was exposed at the bottom

of each cylinder and I used a Dremel to

angle it away from the cylinder to

prevent the piston skirt from contacting

any aluminum (I was concerned about

marring, not sure how valid this is but

better safe than sorry). Also, I will

discuss this more later but I followed

Sid's recommendation to used a bit more

piston to cylinder wall clearance

(0.005" - 0.0055").

5) Deck the block -

Again I relied on my machinist for this.

Make sure to mention to your machinist

that the surface finish of 50 RA or

finer is required for a Cometic head

gasket.

6) Final block cleaning -

Once I got the block back from the

machine shop, I cleaned it using soap

and hot water. I used pipe cleaners to

clean out all oil channels . I used

white grease to coat the iron cylinders

during cleaning with water. I then used

an air hose to blow any water out of all

channels.